Direct metal laser sintering dmls ti64 is characterized by excellent mechanical properties and corrosion resistance as well as low specific weight and biocompatibility.

Direct metal laser sintering price.

200 x 200 x 200 mm.

Ge additive arcam ebm spectra l.

Through impressive metal 3d printers come at a price.

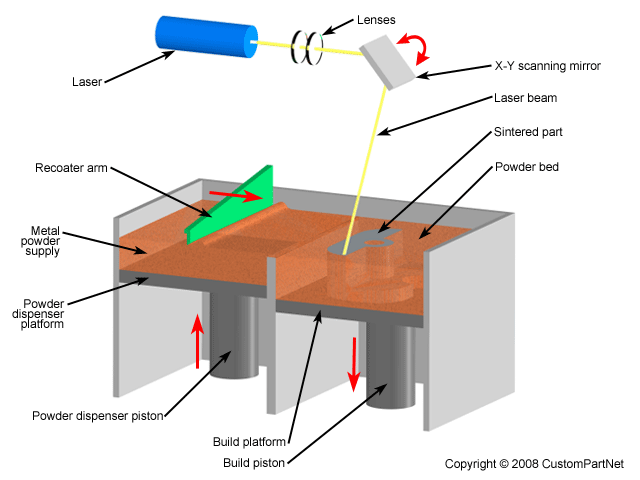

The technology fuses metal powder into a solid part by melting it locally using a focused laser beam.

It creates parts additively by sintering fine metal powder particles to fuse them together locally.

The eos m 290 is a metal 3d printer with direct metal laser sintering technology.

Dmls direct metal laser sintering is an additive manufacturing method.

The parts are built up additively layer by layer.

The eosint m 270 builds metal parts using direct metal laser sintering dmls.

This guide covers the direct metal laser sintering process as well as.

Direct metal laser sintering is a groundbreaking metal 3d printing technology.

Dmls is able to support internal design features that cannot be created by other machining processes allowing for greater design innovation.

Selective laser sintering sls is an additive manufacturing am technique that uses a laser as the power source to sinter powdered material typically nylon or polyamide aiming the laser automatically at points in space defined by a 3d model binding the material together to create a solid structure it is similar to selective laser melting.

With international certification standards iso 9001 and as9100 we have stringent systems in place to guarantee quality and consistently are met.

ø 100 x 95 mm.

Direct metal laser sintering is the most widely used metal 3d printing technology.

Direct metal laser sintering.

Many major valuable 3d printing companies including 3d systems slm solutions concept laser and eos sell dmls metal 3d printers that are able to create incredibly intricate metal parts and 3d printed jewelry from precious metals.

Direct metal laser sintering quality controls to maintain critical quality control standards we use a range of tools to inspect and ensure customer specifications.

ø 350 x 430 mm.

The two are instantiations of the same concept.

Even highly complex geometries can be created directly from 3d cad data fully automatically in just a few hours.

This alloy is ideal for high performance engineering applications such as aerospace and motor racing and for the production of biomedical implants.

It has a powerful 400 watt fiber laser with exceptional high beam quality.

If you buy something through one of those links you won t pay a penny more but we ll get.

Like in the sls process your metal part will be created layer by layer according to your 3d model.

United states 250 000.

Find out how much a metal 3d printer costs by looking at some popular machines on the market.

Ge additive m2 series 5.